0

0SHEET MOLDING COMPOUNDS

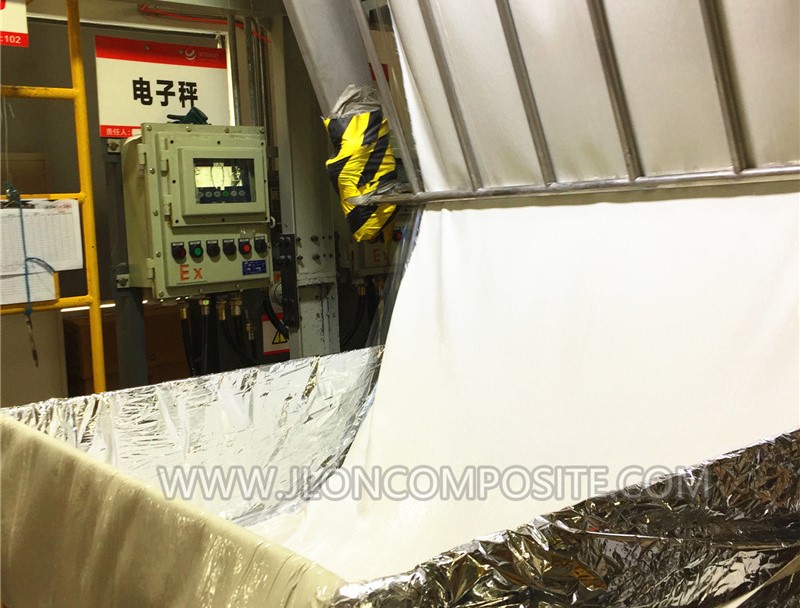

SMC Sheet moulding compound or sheet moulding composite is a ready to mould glass-fibre reinforced polyester material primarily used in compression moulding. The sheet is provided in rolls weighing up to 1000 kg. Alternatively the resin and related materials may be mixed on site when a producer wants greater control over the chemistry and filler.

Sheet moulding compound is manufactured by dispersing long strands (usually >1”) of chopped fiber (commonly glass fibers or carbon fibers on a bath of thermoset resin (commonly polyester resin, vinyl ester resin or epoxy resin)). The longer fibers in SMC result in better strength properties than standard bulk moulding compound (BMC) products. Typical applications include demanding electrical applications, corrosion resistant needs, structural components at low cost, automotive, and transit.

Features:

High mechanical strength, low shrink, low density, dimensional stability, corrosion resistance, fire resistance

Typical Application:

Electrical applications, corrosion resistant needs, structural components at low cost, automotive, sanitary, transit.